Manual Override Capability: Boosting Pneumatic Actuator Performance Efficiency

Within the domain of automation in industry, pneumatic devices play a crucial role in controlling a diverse processes. pneumatic actuator & handwheel make use of air under pressure to generate motion, which makes them critical in systems in which speed and efficiency are paramount. However, the use of compressed air can become problematic, especially during unexpected failures or maintenance shutdowns. This is the point at which the manual override functionality comes into play, offering operators with the power to manage the actuator through manual means when automated control is not feasible.

A pneumatic actuator with manual override enhances performance and reliability, making sure that processes can continue to function smoothly even in difficult conditions. This capability facilitates swift response, giving operators the necessary control to maintain safety and efficiency in operations. With the addition of a manual override, a pneumatic actuator not only boosts flexibility in operations but also considerably decreases downtime, demonstrating its importance for any automation system that values reliability and ease of use.

Comprehending Pneumatic Actuators

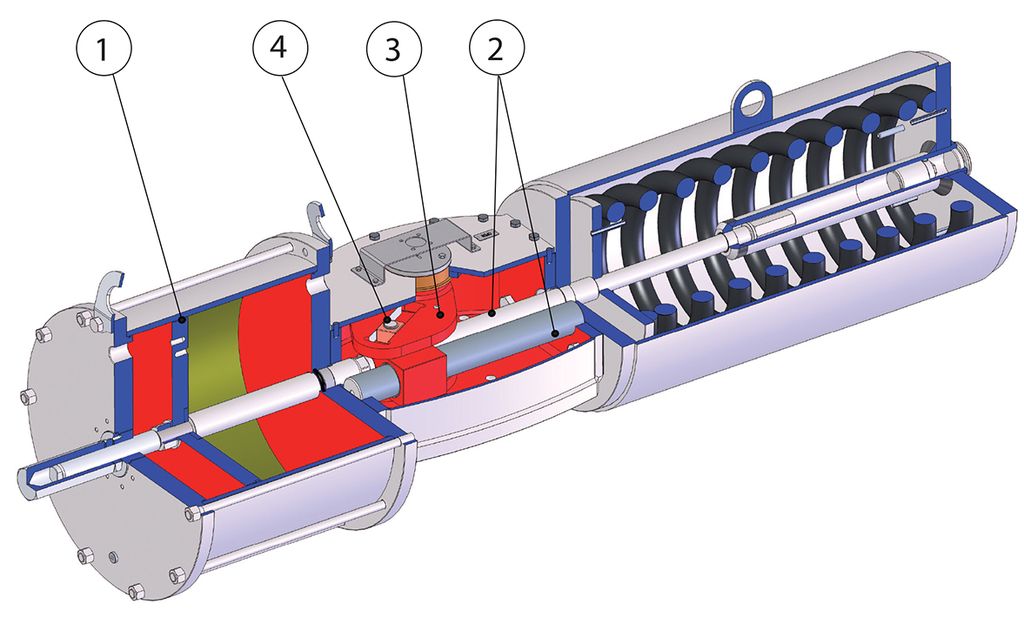

Pneumatic actuators constitute devices that utilize pressurized gas to generate mechanical motion. They have a critical part in diverse commercial applications, allowing exact control of equipment and processes. Through converting the force held in pressurized gas into linear or circular motion, pneumatic devices support the operation of valves, regulators, and other equipment. These devices' quick response times and dependability make them a popular choice in many automated applications.

An important of the key benefits of pneumatic devices is these actuators' simplicity and facility of maintenance. They typically consist of a smaller number of moving components compared to electric or liquid-driven actuators, leading to minimized damage. This intrinsic ease contributes to their long service duration and minimal operational expenses. In addition, pneumatic systems can be used in hazardous environments in which electric sparks may create hazards, making these systems a reliable choice for various sectors.

To enhance the performance of air devices, many installations incorporate a physical override option capability. This ability enables operators to by hand control the actuator in the case of a power failure or maintenance requirement, guaranteeing continuous operation and system reliability. The integration of physical override provides an extra level of adaptability, enabling operators to retain authority of critical operations even in adverse situations.

The Importance of Optional Override

In industries where air-powered actuators are commonly used, the ability to manually override the system is crucial for maintaining oversight and functional efficiency. This functionality provides operators with a reliable means to intercede during unexpected scenarios, such as energy interruptions or automated system malfunctions. When the automated control cannot function, the manual override allows for prompt action, ensuring that processes can continue or be safely halted.

Additionally, manual override capability is invaluable during regular maintenance or diagnostics. Technicians can hands-on engage the actuator to assess its performance without relying solely on automated systems. This hands-on method not only facilitates accurate diagnostics but also enhances the overall dependability of the equipment. The ability to manually adjust or operate the actuator personally contributes to a more secure work environment, as operators can make real-time decisions based on the current condition of the machinery.

Lastly, the integration of a manual override in pneumatic actuators enhances flexibility in operational processes. It allows for rapid adaptations when changing production demands or during technology enhancements. Companies gain advantages from this additional functionality by ensuring that they can quickly respond to any situation, maintaining productivity and minimizing downtime. This adaptability is crucial in the current fast-paced industrial landscape, where productivity and safety are top priorities.

Execution and Benefits

Integrating a pneumatic actuator with operator override features improves operational flexibility in different applications. The operator override allows operators to intervene directly in the case of system failure or service requirements. This capability ensures that processes can carry on running smoothly without complete dependence on mechanized systems, encouraging reliability and resilience.

One of the key gains of including a operator override is the increased safety it provides. In cases where robotic controls may malfunction, operator input allows for immediate action to stop accidents or damage. Operators can easily engage the manual mode, ensuring that they have command over the actuator's movement, which is crucial in emergency cases or when accurate adjustments are necessary.

Additionally, a air-powered actuator with human override streamlines maintenance routines. Technicians can manually operate the actuator during service checks, which allows for easier troubleshooting and more effective repairs. This strategy not only preserves time but also enhances the overall productivity of maintenance operations, ultimately leading to minimized downtime and enhanced productivity in factory environments.